How Concrete Companies are Contributing to This New Movement

If there’s one thing that’s for sure, it’s that being ‘eco-friendly’ is no longer just a trend. Being conscious of the environment is something that every government, company, and person needs to take a new sense of responsibility for. The old linear economy that we are used to, “take, make, and dispose,” isn’t going to work anymore. That’s where a circular economy fits in. Concrete companies are key contributors to this approach.

The idea of a circular economy isn’t brand new, but rather an augmented version of the “reduce, reuse, recycle” model. It involves making the most out of our resources by using each one for as long as possible, as effectively as possible and by regenerating or repurposing each material at the end its life.

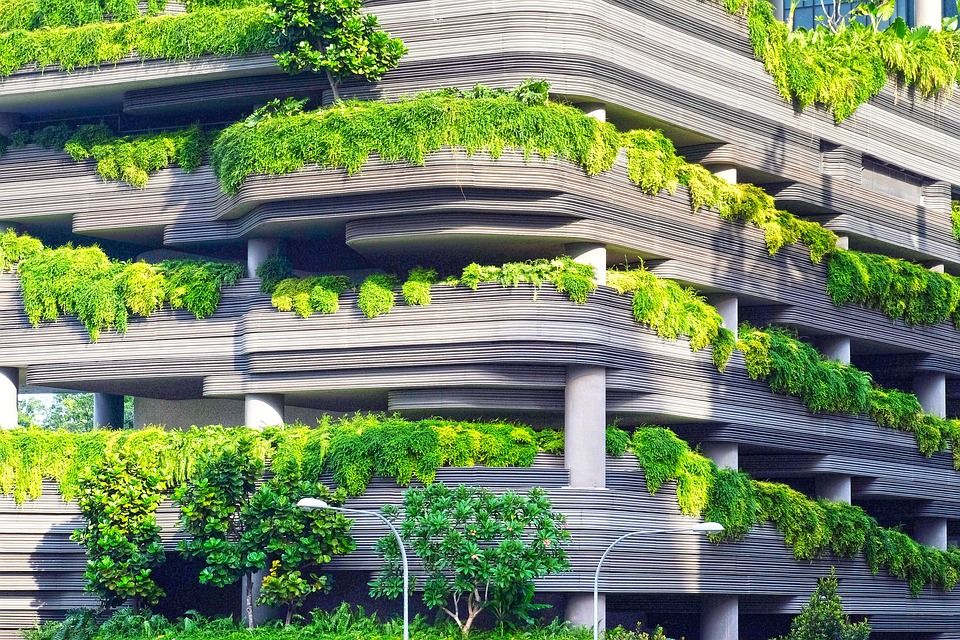

While there are many businesses that have begun to adopt this circular principle, one that plays a particularly central role is the concrete industry. Here are a few of the ways concrete companies help contribute to a circular economy:

- Concrete and cement are made primarily from limestone and aggregates, which are abundantly available. This means the production of these materials does not require using up any scarce or limited resources.

- When concrete companies begin the process of making concrete and cement, the first step is to manufacture clinker. Clinker, which is the main constitute of cement, is made by heating up limestone and aggregates in a kiln. While these kilns are powered by coal and petcoke, concrete companies are now able to use the mineral content of the waste produced as fuel for future manufacturing. This operation of using waste as fuel, also known as co-processing, means a large portion of the raw materials used are recovered and recycled without producing additional waste to do so.

- When manufacturing clinker, concrete companies can also recycle materials and by-products from other industries to use as aggregates, such as fly ash from coal combustion.

- Concrete is 100 percent recyclable. At the end of its life concrete can be repurposed back into concrete or can be used as aggregate, thus giving it a circular life.

- Concrete is highly durable, so even though there may be some waste associated with its manufacturing, the process creates a product that can last for decades.

In Canada, being eco-friendly continues to transition from a trend to a necessity. Fortunately, by ditching the linear economy model there are many ways that Canadian manufacturers, such as concrete companies, can help comply with green initiatives.